MasterTower® incl. crane vacuum technology

The most purchased sheet metal bearing in the world.

The original from 2000 - an investment for generations.

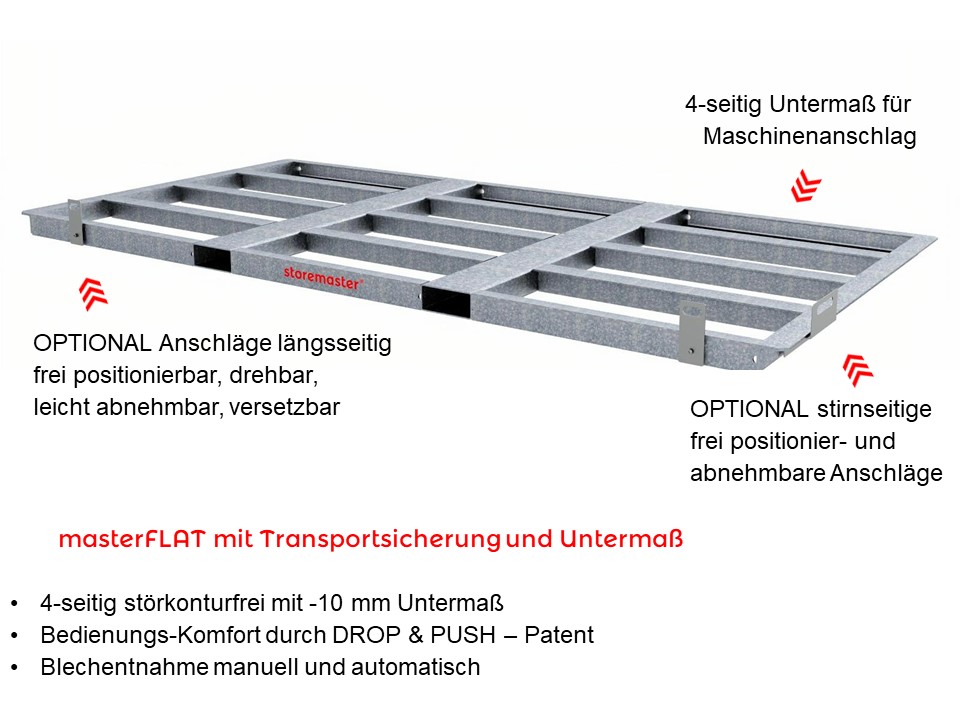

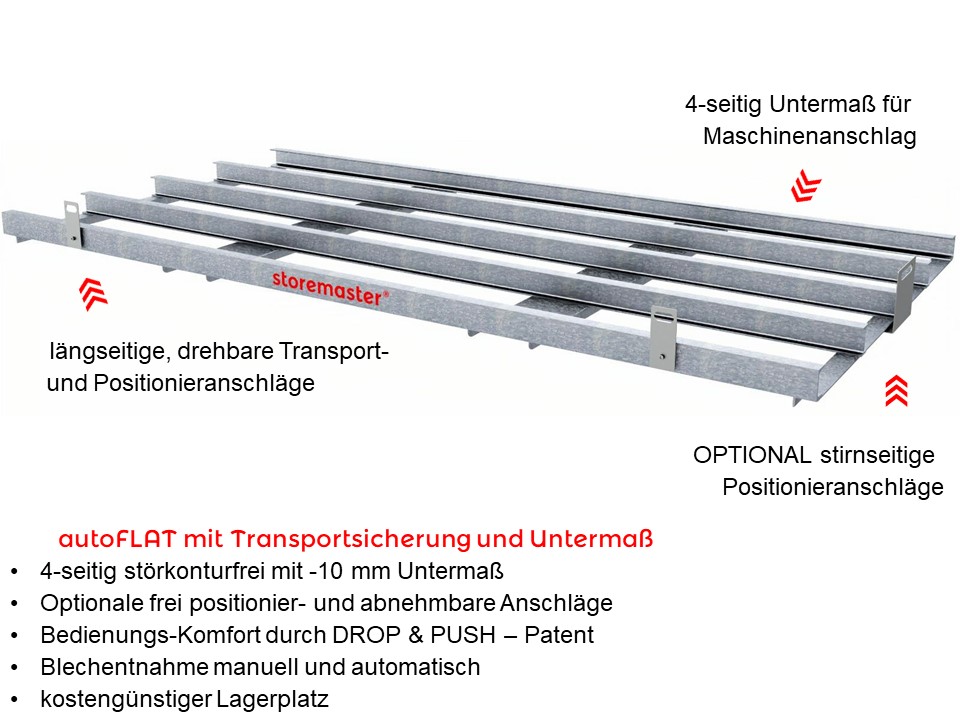

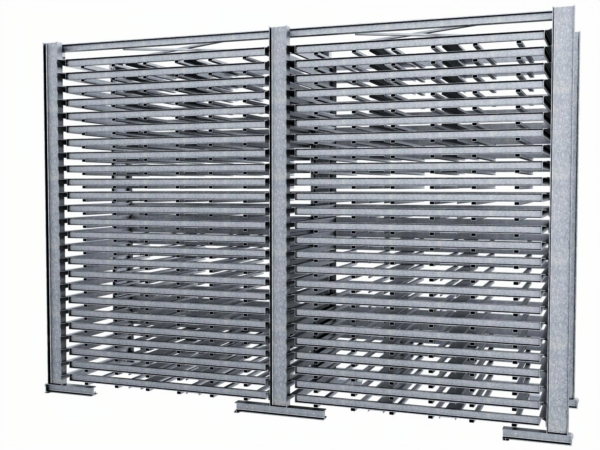

Sheet-metal storage drawer system with retractable pull-out runners, opt. lockable, high load-bearing, permanently lubricated block hinges fix the swing-out walls permanently in their height position, permanently step-free rail transition between block and swing-out rails, as welded - not screwed! Safety at work in accordance with international standards, system assembled ready for operation - optional pull-outs electrified. Uprights in torsion-resistant L-frame construction for permanent perpendicularity ► 20-year functional guarantee; automatic locking devices secure the rest and working position of the drawers without manual operation of mechanical locks for drawers with a payload ≤ 2,000 kg; push spring servo patent facilitates the extension of heavy-duty drawers with a payload ≥ 2,500 kg.

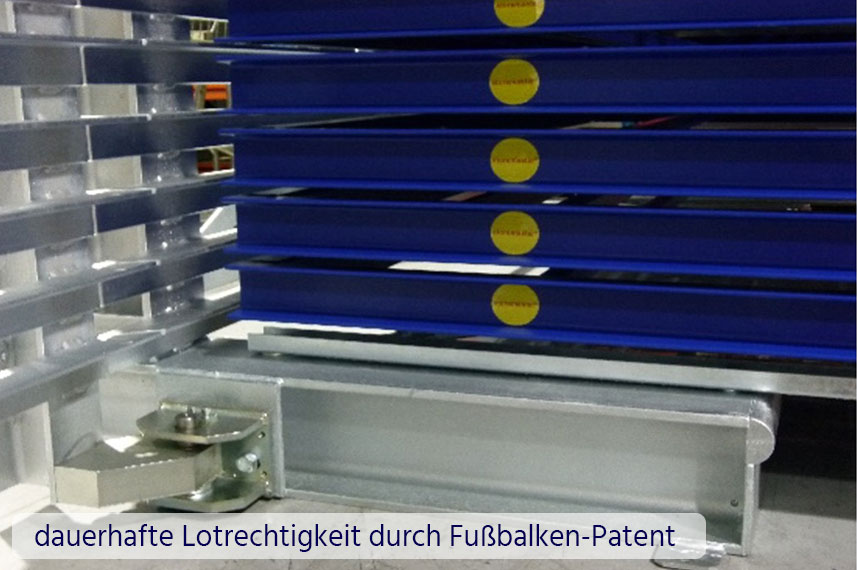

Sheet-metal bearing pull-out system with retractable pull-out roller cheeks, permanently step-free rail transition between block and swivel rails, as welded - not screwed! Uprights in torsion-resistant L-frame construction for permanent perpendicularity ► 20-year functional guarantee - an investment for generations.

Functional safety with retractable pull-out side-panels:

The roller and flange guides on the running surfaces of the runners alone reliably secure the drawers against falling without additional BG-compliant measures in case of additional lateral forces (e.g. forklift impacts). Strong magnets automatically fix the swung-out pull-out drawer runners in their 90° position without the need for BG-compliant mechanical-manual locks.

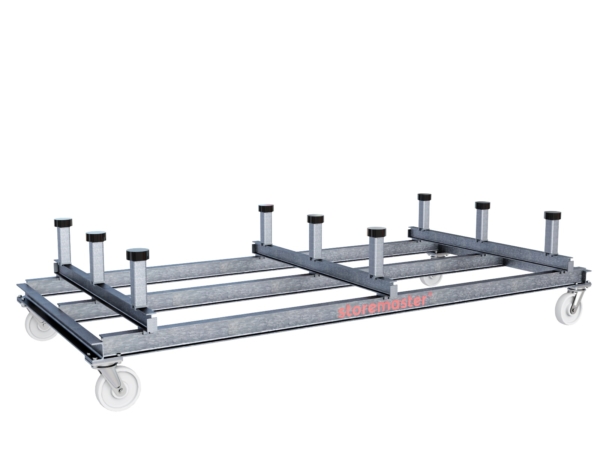

The storemaster® - Rolling comfort for systems with compartment pull-outs:

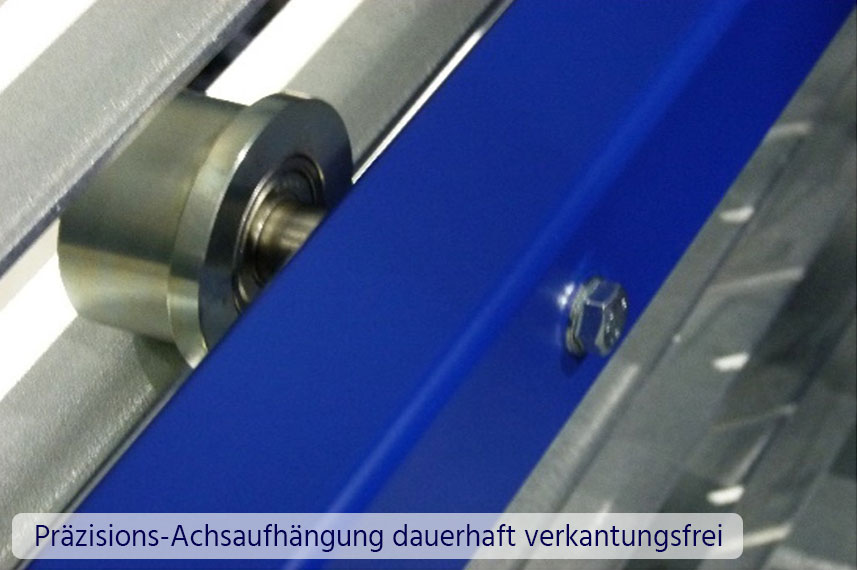

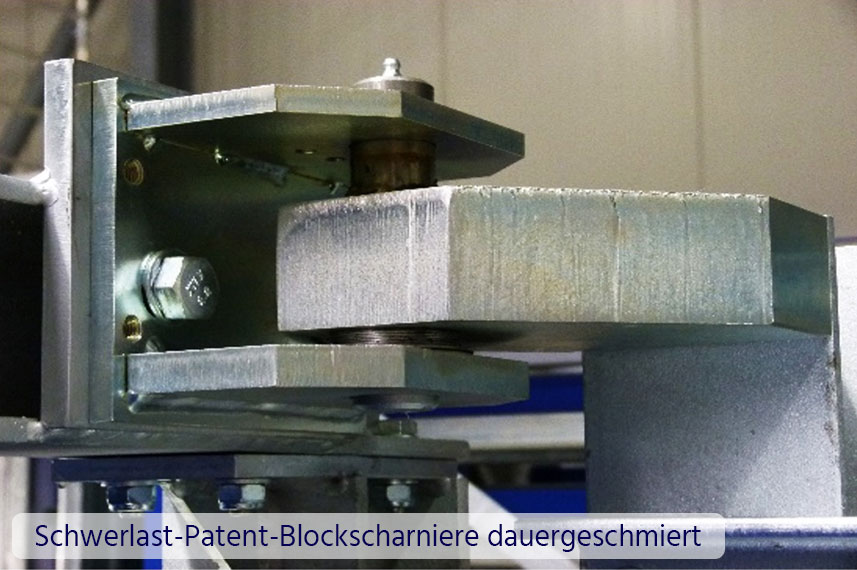

Each interchangeable trolley runs in 8 bearings in special smooth-running ball bearings on chromated solid steel flanged wheels (no lightweight sheet metal housing rollers or ball bearings misused as wheels) with double axle bearings safely and without tilting on hot-dip galvanised (10 times more abrasion-resistant than painted surfaces), smooth running rails without dirt pockets, as there are no upturned or folded edges. Perfect fall protection with automatic function in accordance with UVV (accident prevention regulations) with swivel-in design. Special heavy-duty precision block hinges with permanent lubrication ensure a permanently heel-free rail transition into the pull-out area with retractable pull-out side-panels - durable and maintenance-free.

Occupational safety and accident prevention (occupational health and safety) according to international standards:

storemaster® fulfils the following UVV occupational health and safety requirements which cannot be remedied by rectification, without which commissioning of the product permanently endangers the BG insurance protection: Exclusion of human error due to failure to operate safety devices:

- automatic Fixing of swung-out roller rail walls without manual brakes

- automatic Support for swung-out roller rail walls without manual brakes

- automatic Tilt protection of the roller runner walls against drawer fall-out

- Self-acting drawer fall protection through automatic locking Between pull-out runners and pull-out drawer

without loss of rolling comfort - without manual locking device