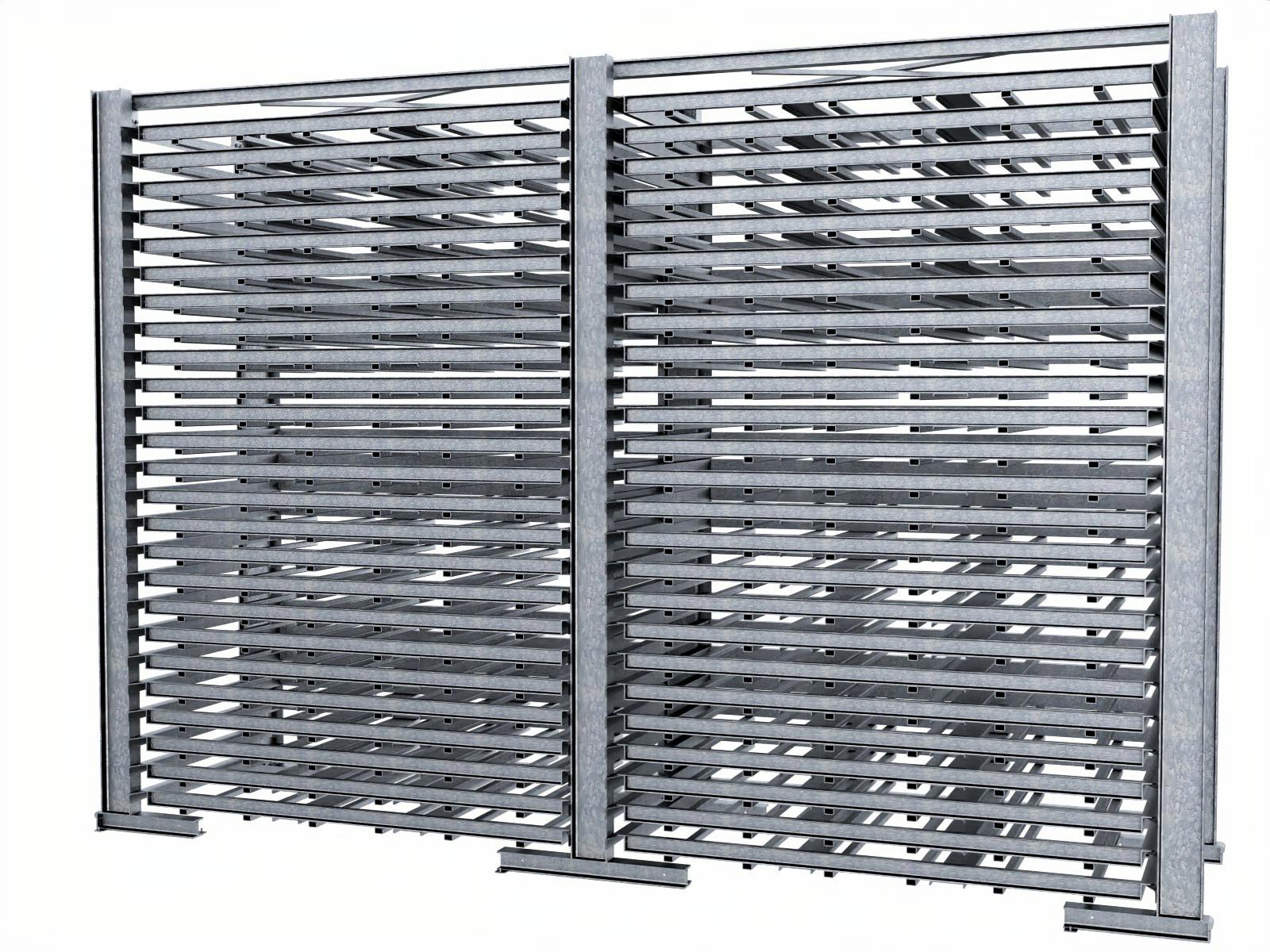

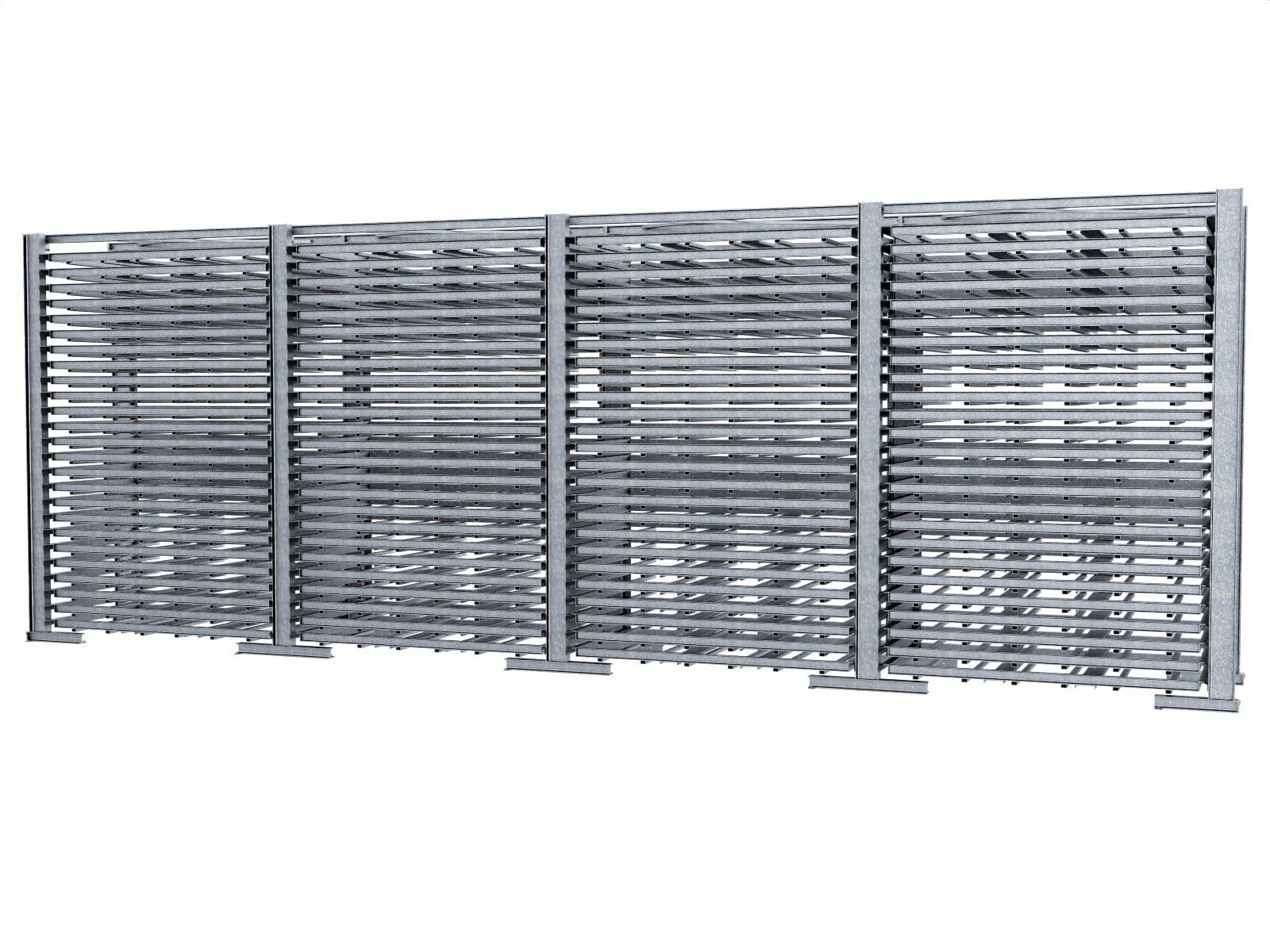

ShuttleTower® slide-in pallet system.

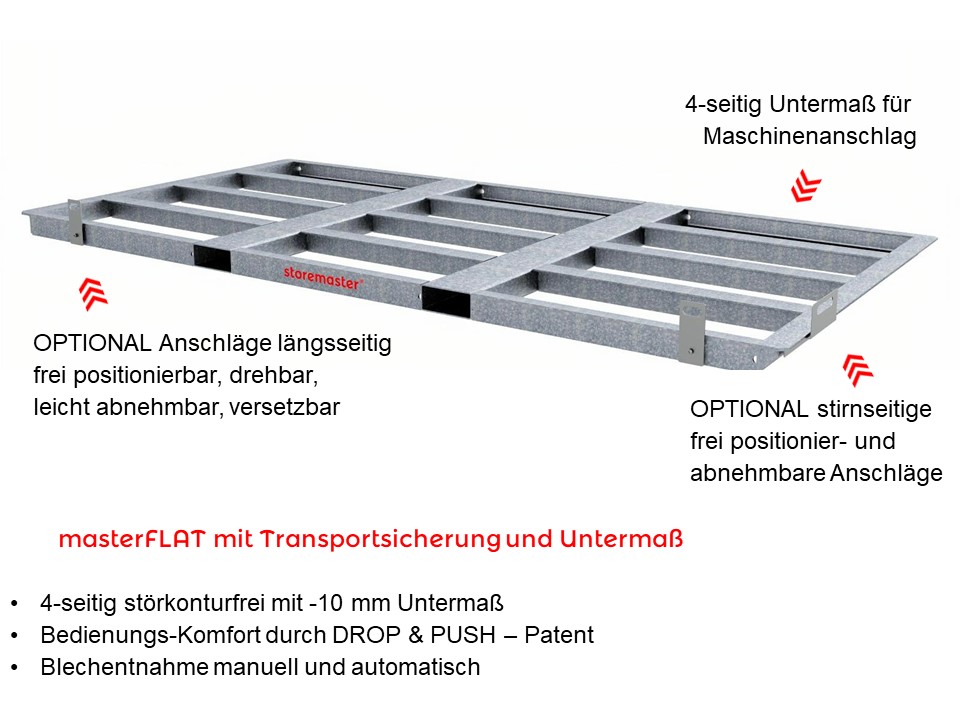

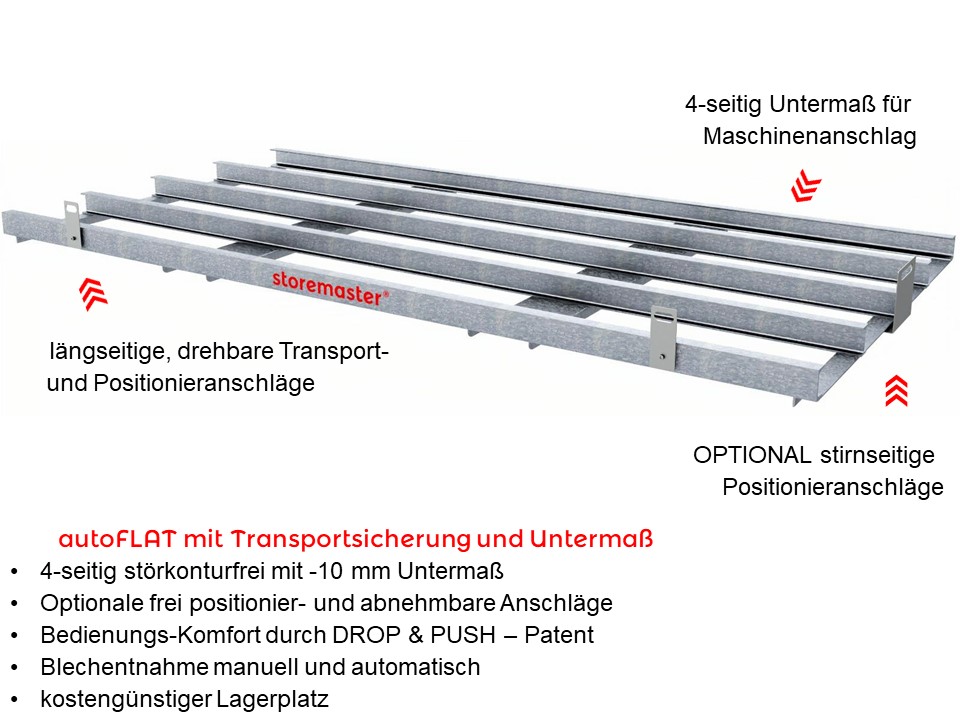

The storemaster® Sheet metal storage system ShuttleTower® with the load carrier superFLAT stands for an exclusively highly compressed storage density to save valuable storage space. The extremely high operational safety during transport (slipping out) and storage is achieved by the impact-resistant all-round protection of the sheet metal package inside the load carrier. superFLAT. The frame height is identical to the max. height of the sheet metal package. For higher packages, optional safety pins can be provided. An appropriate all-round clearance simplifies loading and also allows untrimmed sheets to be picked up, as well as by means of the storemaster®-The forks are also available in a deep-web design for alternative loading by belt. The surface is permanently protected against impact and corrosion by hot-dip galvanising in accordance with DIN EN ISO 1461. The open forklift shoes with the increased entry dimension for the forks protect the forklift from losing its stability (risk of tipping over) in the event of unevenly distributed loads contrary to BG regulations (tube shoes only on special customer request).

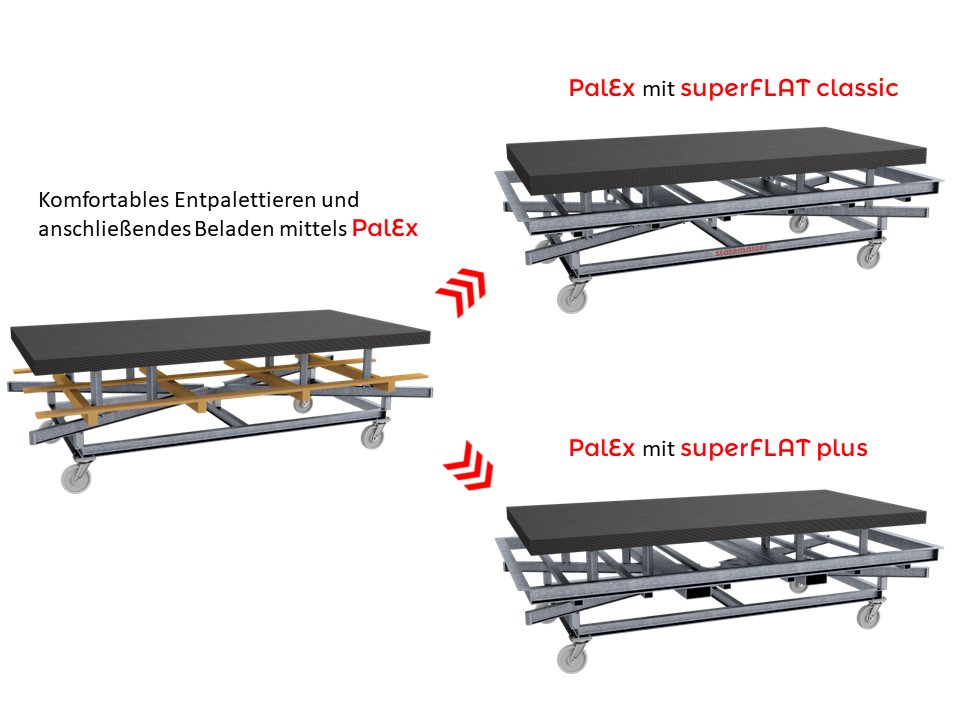

To remove a sheet from the sheet package by hand, the load carrier is placed on the machine on a stamping table (or PalEx) - the load carrier is lowered - the bundle of sheets lies freely on 4 sides on 15 movable punches of the punching table - the top sheet can now be pulled off freely on all 4 sides without any directional instructions and without having to remove any pins. After sheet removal, the sheet package is safely placed in the cassette again for transport by simply lifting the load carrier.

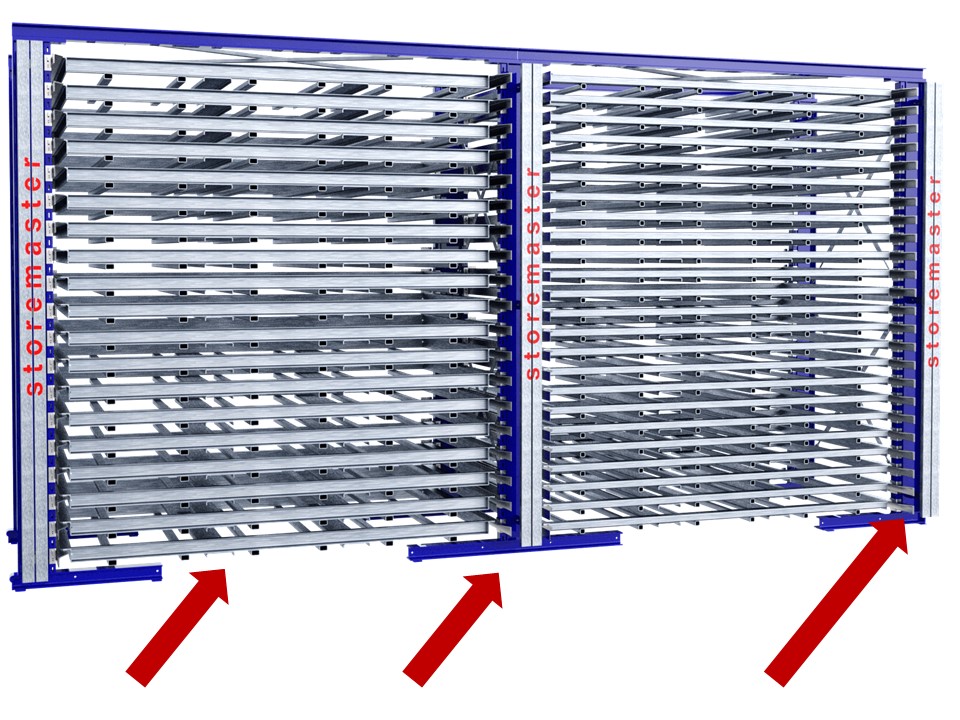

The upright (tower load 150 t) in welded L- and T- upright frame construction with foot beams pointing inwards for rigid absorption of the diagonal forces in the longitudinal direction of the racking for a permanently stable vertical position of the columns (6-pane stable) is the prerequisite for unlimited guaranteed functionality. In this way, rear diagonal bracing can be dispensed with if there is a risk of their destruction by overlong forks.

The occasional need to adapt to changing shelf heights is made possible by the rail plug-in grid of 75:75 mm.

Apart from the above, the most decisive unique selling proposition for the user is the unique

Drop & Push - storage convenience patent with the force-guided angle-on-angle insertion already in front of the front of the stored pallets. This eliminates the tedious threading into the compartment gap with the simultaneous most effective avoidance of damage of any kind to the sheet metal package, upright or system pallet through a guaranteed safe, collision-free and time-saving storage process.